We spoke with Emma Richardson, a nursery school teacher from Bristol who turned her evening craft hobby into a £2,000-per-month side business using a desktop print cutter. She shares the honest numbers, unexpected challenges, and real calculations that helped her machine pay for itself in just seven months.

The Question Everyone Asks: “Will It Actually Make Money?”

If you’re reading this, you’ve probably spent hours scrolling through Instagram feeds filled with beautifully cut vinyl decals, custom stickers, and personalised gifts. You’ve watched YouTube videos about print-on-demand businesses, passive income streams, and “how I made £5,000 my first month” success stories. And you’ve asked yourself one critical question: Can I actually make money with a desktop print cutter, or is this just an expensive hobby?

The honest answer? It depends entirely on your approach, realistic expectations, and willingness to treat it like a business rather than a hobby.

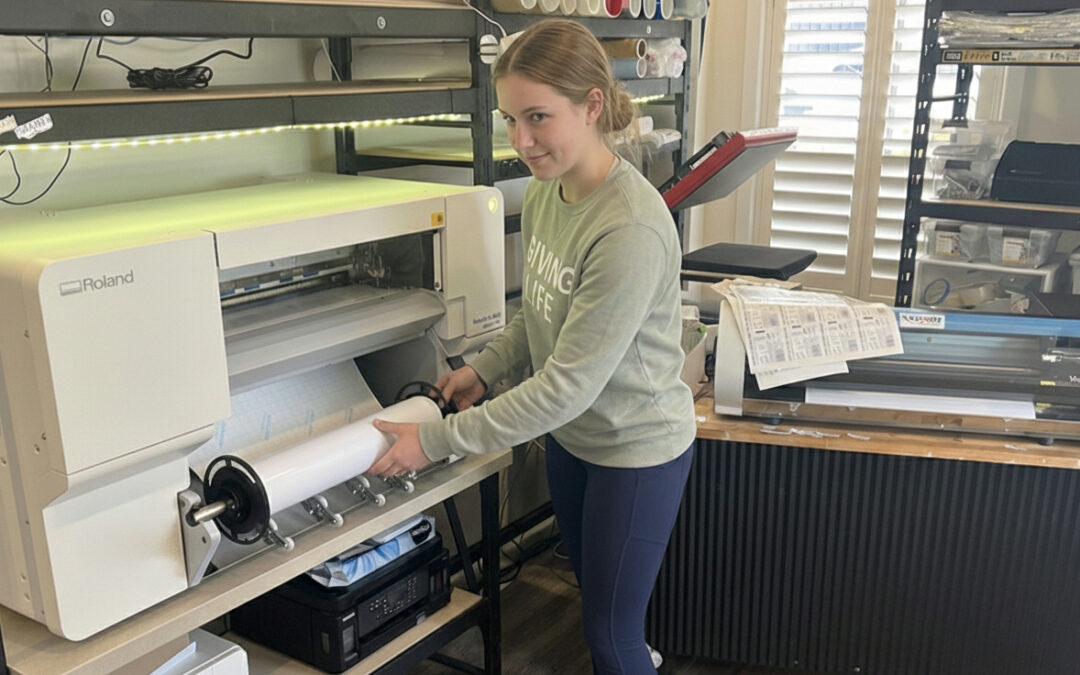

We sat down with Emma Richardson, a 34-year-old primary school teacher from Bristol who bought a Roland BN2-20A desktop printer/cutter in May 2025. She was refreshingly honest about what worked, what didn’t, and the real numbers behind her side business journey.

Spoiler: Her machine paid for itself, but not in the way she initially expected. No viral TikTok moments, no overnight success—just consistent effort, smart niche selection, and ruthless focus on profit margins.

Emma Richardson in her Bristol home office where she runs her side business alongside teaching full-time

Meet Emma: The Reluctant Entrepreneur

RGB UK: Emma, thanks for talking to us. Let’s start with the basics—what made you consider buying a print cutter in the first place?

Emma: Honestly? I was burned out from teaching and needed a creative outlet. I’d been making personalised water bottles for my Year 3 class using cheap vinyl from Amazon and a £200 Cricut. Parents kept asking if I could make them for their kids, and I started thinking—maybe there’s something here? But I also knew the Cricut had serious limitations. I couldn’t print designs, only cut solid colours, which ruled out most of what I actually wanted to make.

RGB UK: What made you leap from a £200 hobby machine to a professional desktop print cutter? That’s quite a jump.

Emma: [Laughs] My husband thought I’d lost the plot, to be honest. But I did the maths. I was spending about £80 a month on vinyl, transfer tape, and supplies, making maybe £150-£200 selling bottles and laptop stickers at school events. The profit was pathetic once I factored in my time. I realised if I was serious about this, I needed to either quit or properly invest. The middle ground was just… expensive therapy.

RGB UK: So how much did you actually invest to get started properly?

Emma: Right, let me grab my spreadsheet—I’ve tracked every penny. [Pause] Okay, here we go:

The Roland BN2-20A: Emma’s investment that transformed her hobby into a profitable business

Emma’s Initial Investment (May 2025)

| Item | Cost |

|---|---|

| Roland BN2-20A (financed over 12 months) | £5,000 |

| Additional CMYK ink cartridges (backup set) | £180 |

| Printable vinyl rolls (3 x white, 2 x clear) | £340 |

| Heat transfer material starter pack | £120 |

| Transfer tape, weeding tools, squeegees | £85 |

| Etsy shop setup + business cards | £60 |

| Adobe Creative Cloud (annual) | £240 |

| Total Initial Investment | £6,025 |

Emma: That’s just the start-up. Monthly, I was paying £350 for the finance, plus about £15 for Adobe, £20 for Etsy fees, and variable costs for materials depending on orders. So roughly £400-£500 monthly overhead before making anything.

RGB UK: That’s a significant commitment. Were you terrified?

Emma: [Laughs] Absolutely. I remember sitting in the car after leaving RGB UK with the machine thinking, “What have I just done?” My teacher salary is decent but not “throw £5,000 at a side business” decent. But I also knew myself well enough to know I wouldn’t take it seriously without skin in the game.

Month One: The Brutal Reality Check

RGB UK: Walk us through your first month. What happened?

Emma: [Sighs] It was humbling. I had this naive vision where I’d post my Etsy shop, orders would flood in, and I’d be making hundreds in profit immediately. The reality was… three orders in the first three weeks. Total revenue: £47. My profit after materials and fees? About £18.

I’d spent hundreds of hours setting up the shop, learning the BN2-20A software, practising cuts, and designing products. If I’d been tracking hourly rate, I was earning about 30p per hour. It was crushing.

RGB UK: What changed?

Emma: Two things. First, I stopped trying to compete in oversaturated markets. Everyone and their nan is selling generic “wine o’clock” decals and “mama bear” tumblers. I was drowning in a sea of sameness. Second, I got ruthlessly honest about pricing.

Here’s what I learned: If you’re not charging enough to make at least 60% profit margin, you’re running a charity, not a business. And in competitive niches, you can’t charge enough to hit that margin because customers won’t pay £15 for a water bottle sticker they can get for £4.99 elsewhere.

Finding a Profitable Niche: The Turning Point

RGB UK: So what niche did you find?

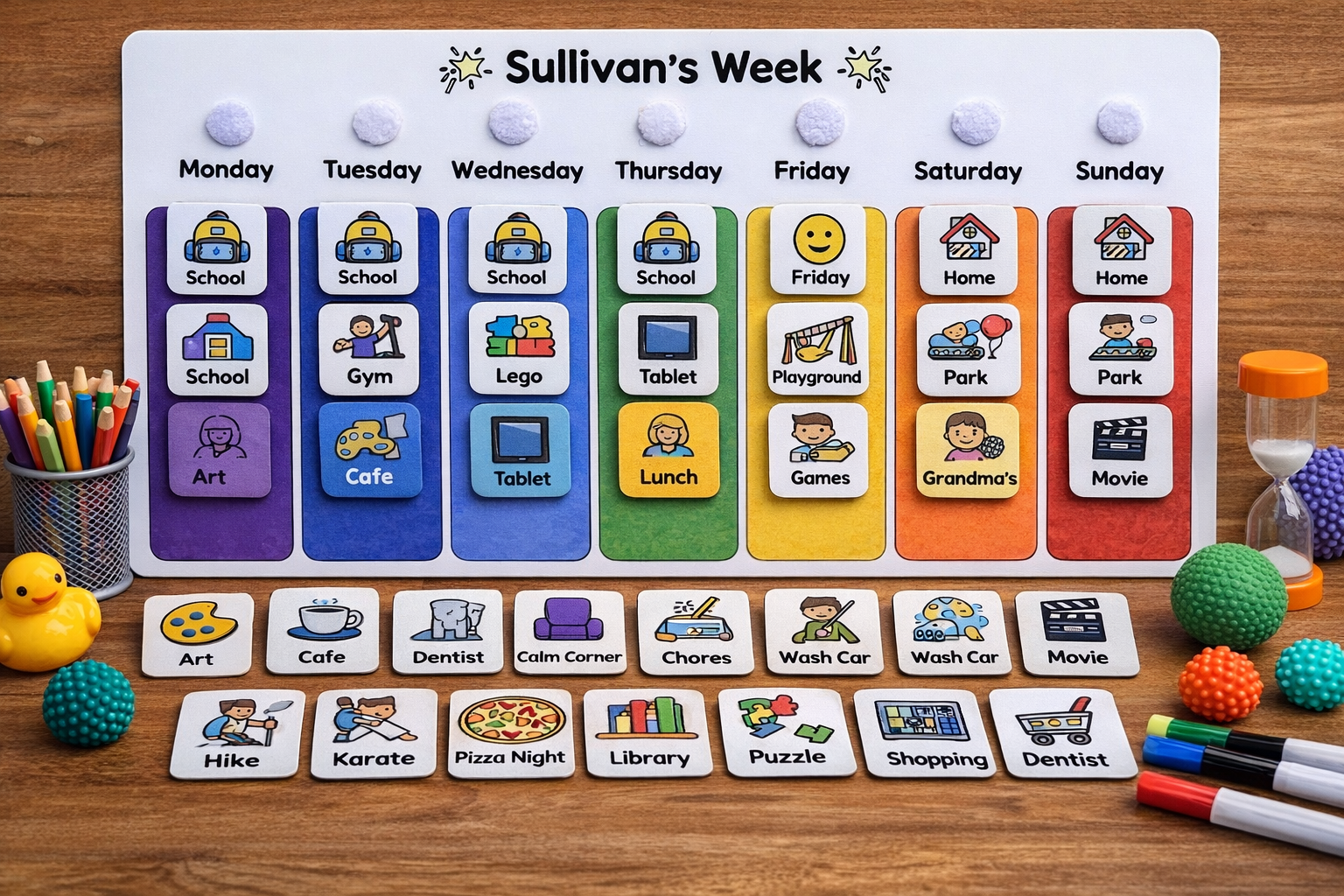

Emma: Special educational needs resources and classroom labels. It sounds incredibly boring compared to trendy Instagram products, but hear me out. I’m a SENCO [Special Educational Needs Coordinator], so I understand exactly what teachers and SEN parents need. Visual timetables, communication cards, sensory labels, personalised reward charts—these are specialised products that most Etsy sellers don’t understand or can’t create effectively.

More importantly, the market isn’t saturated because it requires actual expertise. Parents and schools will pay premium prices—£25-£40 for a full personalised visual schedule set—because they desperately need something that works, and they can’t find it in mainstream shops.

RGB UK: Brilliant. What’s your typical profit margin on those products?

Emma: Let me show you a real example. My bestseller is a personalised visual timetable set with Velcro-backed cards:

Examples of Emma’s SEN visual timetable sets – her most profitable product line

Product Costing Example: SEN Visual Timetable Set

| Cost Component | Amount |

|---|---|

| Selling Price (Etsy) | £35.00 |

| Less: Etsy fees (6.5% + 20p) | -£2.48 |

| Less: Payment processing (4%) | -£1.40 |

| Less: Printable vinyl (A4 sheets x5) | -£3.20 |

| Less: Ink cost estimate | -£0.80 |

| Less: Velcro dots (50 pieces) | -£1.50 |

| Less: Packaging & postage | -£2.90 |

| Net Profit per Unit | £22.72 |

| Profit Margin | 64.9% |

Emma: Production time is about 35 minutes including design customisation, printing, cutting, weeding, and assembly. So my effective hourly rate is around £38-£40, which is considerably better than my teaching salary when you factor in holidays and marking!

RGB UK: That’s impressive. But surely SEN products are a limited market?

Emma: You’d think so, but there are over 1.5 million children with SEN in UK schools alone, plus countless adults using visual supports. The market is actually substantial and underserved. I’ve had schools order multiple sets for their SEN units. My record month was October 2025—£2,340 in revenue from just SEN products.

Diversification: Not Putting All Eggs in One Basket

RGB UK: Do you only sell SEN products?

Emma: No, that would be risky. SEN is my primary income stream—about 65% of revenue—but I also do:

- Heat transfer designs for local sports clubs: This was unexpected. A parent runs a junior football club and asked if I could do custom t-shirts. I now do regular bulk orders for three local clubs. Lower margin (40-45%) but consistent monthly income.

- Personalised teacher gifts: Peak season is July and December. I make decent money on “Thank You Teacher” gifts, but it’s seasonal and I don’t rely on it year-round.

- Small signage for local businesses: Window hours stickers, staff name badges, simple A4 promotional signs. This came through word-of-mouth. Again, not huge money, but it fills quiet weeks.

RGB UK: Smart. What about the markets everyone talks about—custom mugs, tumblers, that sort of thing?

Emma: [Laughs] I tried. Bought a heat press, ordered blanks, made samples. The market is absolutely rammed. You’re competing with people who’ve bought containers of blank tumblers from China and can undercut you on everything. Unless you have a massive social media following or a unique design aesthetic, it’s a race to the bottom on pricing.

I made exactly £127 profit over three months selling tumblers, working maybe 30 hours. That’s £4.23 an hour. I sold the heat press on Facebook Marketplace and refocused on what was actually profitable.

RGB UK: That’s refreshingly honest. Most “side hustle” content glosses over failures.

Emma: Because admitting you wasted £400 on a failed product line isn’t very “inspirational content,” is it? [Laughs] But it’s important. I see people on Facebook groups asking whether to buy a print cutter for “general crafts” and expect to make thousands immediately. The honest answer is: probably not. You need a specific niche, real expertise, and willingness to fail expensively before you find what works.

The Numbers: When Did It Actually Pay for Itself?

RGB UK: Let’s talk about the question everyone wants answered. When did your BN2-20A pay for itself?

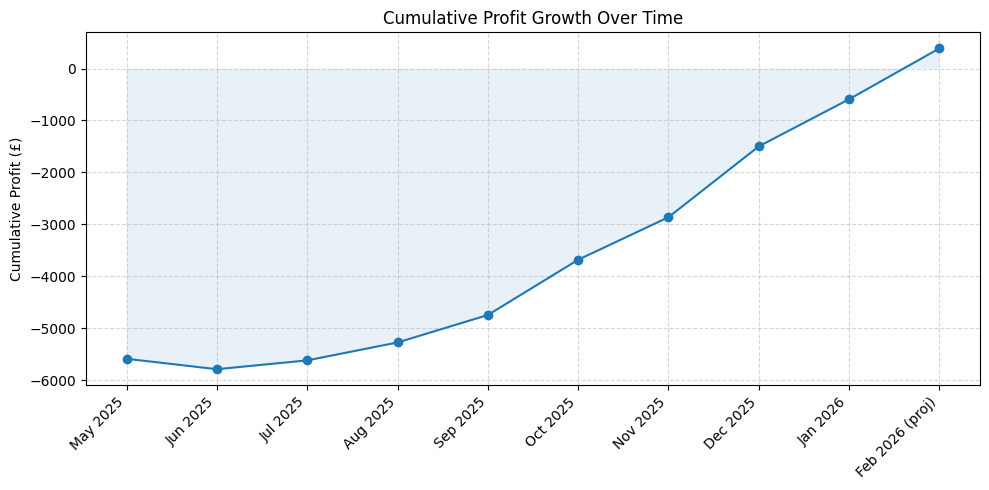

Emma: Define “pay for itself.” If you mean when did cumulative profit equal my initial £5,225 investment? Month seven—December 2025. But that’s not the full picture.

Here’s my actual month-by-month breakdown:

Emma’s Monthly Performance (May 2025 – January 2026)

| Month | Revenue | Materials | Fixed Costs | Net Profit | Cumulative |

|---|---|---|---|---|---|

| May 2025 | £47 | £29 | £385 | -£367 | -£5,592 |

| June 2025 | £283 | £98 | £385 | -£200 | -£5,792 |

| July 2025 | £842 | £287 | £385 | £170 | -£5,622 |

| August 2025 | £1,124 | £394 | £385 | £345 | -£5,277 |

| September 2025 | £1,456 | £512 | £415 | £529 | -£4,748 |

| October 2025 | £2,340 | £831 | £445 | £1,064 | -£3,684 |

| November 2025 | £1,893 | £658 | £415 | £820 | -£2,864 |

| December 2025 | £2,785 | £976 | £445 | £1,364 | -£1,500 |

| January 2026 | £1,987 | £694 | £385 | £908 | -£592 |

| February 2026 (proj.) | £2,100 | £735 | £385 | £980 | +£388 |

| Total Profit to Date (9 months) | £4,633 | ||||

Note: Fixed costs include finance payment (£350), software (£15), Etsy fees (£20), and electricity estimate. Material costs include all vinyl, ink, packaging, and consumables.

Emma: So technically, if February goes as projected, I’ll have fully recovered my initial investment by month 10. But here’s what’s more important: from month 7 onwards, I’ve been generating £800-£1,300 in monthly profit consistently. That’s real money that’s paid for family holidays, helped with mortgage overpayments, and given us breathing room financially.

Emma’s journey from loss to profit – the first three months were challenging

The Hidden Cost: Time Investment

RGB UK: What about time? How many hours are you actually working?

Emma: This is crucial and something most people underestimate. In my peak month—December 2025—I worked approximately 65 hours over evenings and weekends. That’s £1,364 profit divided by 65 hours, or about £21 per hour. Decent, but not life-changing when you factor in that it’s my “relaxation time” being consumed.

Average months are more like 35-40 hours. My current effective hourly rate sits around £20-£25, which is actually less than my teaching overtime rate. But here’s the difference: I control this. No meetings, no Ofsted, no behaviour management. I put headphones on, listen to audiobooks, and make things. The mental health value is significant even if the hourly rate isn’t spectacular.

RGB UK: Would you do it again knowing what you know now?

Emma: Yes, but with different expectations. I thought this would be a passive income stream where I’d design products once and money would roll in. The reality is it’s a proper part-time job. Every order requires work—customisation, communication, production, packaging, posting.

If someone asked me today whether they should buy a desktop print cutter to make money, I’d ask them:

- Do you have a specific niche with genuine expertise?

- Can you commit 30-40 hours monthly consistently for at least six months before seeing profit?

- Are you comfortable with the business being seasonal and unpredictable?

- Do you have enough financial cushion to survive months where you make £200 profit?

If they answer no to any of those, I’d suggest they keep their hobby as a hobby rather than creating an expensive obligation.

The Challenges Nobody Talks About

RGB UK: What have been your biggest challenges?

Emma: [Deep breath] Where do I start?

Market saturation in obvious niches: I wasted so much time trying to compete with established sellers in oversaturated markets. If you search “custom tumbler” on Etsy, there are literally hundreds of thousands of listings. Standing out requires either massive marketing budgets or viral social media luck—neither of which I had.

Customer expectations vs. reality: People expect Amazon Prime delivery speeds and professional studio photography but want to pay craft fair prices. Managing that expectation gap is exhausting. I’ve had customers leave three-star reviews because their personalised item took five days to arrive—despite me clearly stating 5-7 day turnaround.

The mental load: This isn’t just making stickers. It’s customer service, photography, social media marketing, inventory management, accounting, and actual production. Some weeks I spend more time answering messages than making products.

Guilt about saying no: When you run a small business, there’s pressure to accept every order, work weekends, respond to messages at 11pm. Learning to set boundaries—”I don’t do rush orders,” “I can’t create that design,” “No, I won’t discount for bulk orders under 20 units”—was really difficult for me.

Equipment issues: The BN2-20A is reliable, but I’ve had ink cartridges fail, cutting blade issues, and one terrifying firmware update that temporarily bricked the printer. When your income depends on one machine and it goes down, the stress is real.

RGB UK: How did you handle the printer issue?

Emma: Panicked initially! [Laughs] But I called RGB UK and they talked me through a reset procedure. It was actually user error—I’d interrupted an update. But it highlighted how vulnerable you are when you’re a one-person operation with one machine. I don’t have a backup printer or the space for redundancy.

Let’s Talk About Market Saturation

RGB UK: You mentioned saturation. How bad is it really in different niches?

Emma: Right, this is important because most YouTube videos gloss over this. Let me break down what I’ve observed:

Oversaturated (Don’t Bother Unless You Have Unique Advantage):

- Generic tumblers/water bottles: Absolutely rammed. Thousands of sellers, race-to-the-bottom pricing, identical designs. Average profit margin I managed: 25-30%. Not worth it.

- “Wine o’clock” / “Mama bear” style decals: Everyone making identical products targeting the same Facebook groups. Customers expect £3.99 prices. Can’t compete.

- Car decals (names, stick families, etc.): Massive competition from sellers who buy wholesale and can undercut you significantly.

- General wall quotes: Unless you’re a talented designer creating truly original designs, you’re competing with people selling identical “Live Laugh Love” stickers for pennies.

Moderately Saturated (Possible with Good Branding/Niche):

- Wedding/event stationery: Competitive but premium customers will pay for quality and personalisation. Requires strong design skills and excellent customer service. Profit margins 45-55% if you position correctly.

- Small business branding (logos/window decals): Local market can support this if you network well. One-off jobs rather than scalable, but decent hourly rate.

- Sports team customisation: Clubs need regular orders. Once you’ve secured them as clients, it’s consistent income. Margin 40-50%.

Underserved (Where I Found Success):

- Specialist educational resources: SEN, classroom management, visual supports. Requires actual expertise but premium pricing possible. Margin 60-70%.

- Industry-specific tools: Think warehouse labels, safety signage, specialist equipment marking. Boring but profitable. Margin 55-65%.

- Accessibility products: Visual aids for elderly care, dementia-friendly labels, accessibility signage. Growing market, limited competition. Margin 60-70%.

RGB UK: So your advice is to avoid popular trending products?

Emma: Not necessarily avoid them, but understand you’re entering a knife fight. If you have 50,000 Instagram followers or unique artistic talent, maybe you can carve out space in saturated markets. But for normal people like me? Find something boring that requires actual knowledge or expertise. Everyone wants to sell pretty Instagram-worthy products. Almost nobody wants to make visual timetables for autistic children or dementia-friendly drawer labels. But those customers desperately need them and will pay properly.

Why the Roland BN2-20A Specifically?

RGB UK: You chose the BN2-20A over cheaper alternatives. Was that the right decision?

Emma: Absolutely. I nearly bought a cheaper Chinese import printer/cutter to save £1,500. Thank God I didn’t. Here’s why the BN2-20A was worth the premium:

Print quality: At 1,440 dpi, the output is genuinely professional. My SEN visual cards have fine text and detailed symbols that cheaper printers just can’t reproduce cleanly. When schools are paying £35 for a set, they expect professional quality.

Integrated workflow: Print and cut in one machine without manually aligning or using separate equipment. This saves enormous amounts of time. I can set up a job, walk away, and come back to finished products ready for weeding. Time is money when you’re doing this around a full-time job.

Reliability: Nine months in, aside from that user-error firmware panic, it’s been rock solid. I’ve read horror stories in Facebook groups about cheap machines breaking constantly, parts being unavailable, or tech support consisting of broken English emails from overseas. When the BN2-20A had a minor cutting issue, RGB UK answered immediately and sent a replacement part next day.

Software: VersaWorks 7 and FlexiDESIGNER VersaStudio are included and actually good. I don’t need to buy additional expensive RIP software or struggle with clunky knockoff programs.

Resale value: If this venture had failed completely, Roland equipment holds value. I could have sold the BN2-20A for probably 60-70% of purchase price. Cheap imports have essentially zero resale value.

RGB UK: Any downsides to the BN2-20A?

Emma: It’s not huge, but the 20-inch width does limit me occasionally. I’ve had requests for larger signage that I can’t fulfil. If I was doing this full-time, I’d probably consider upgrading to a 30-inch model. But for part-time side business, 20 inches handles 95% of what I make.

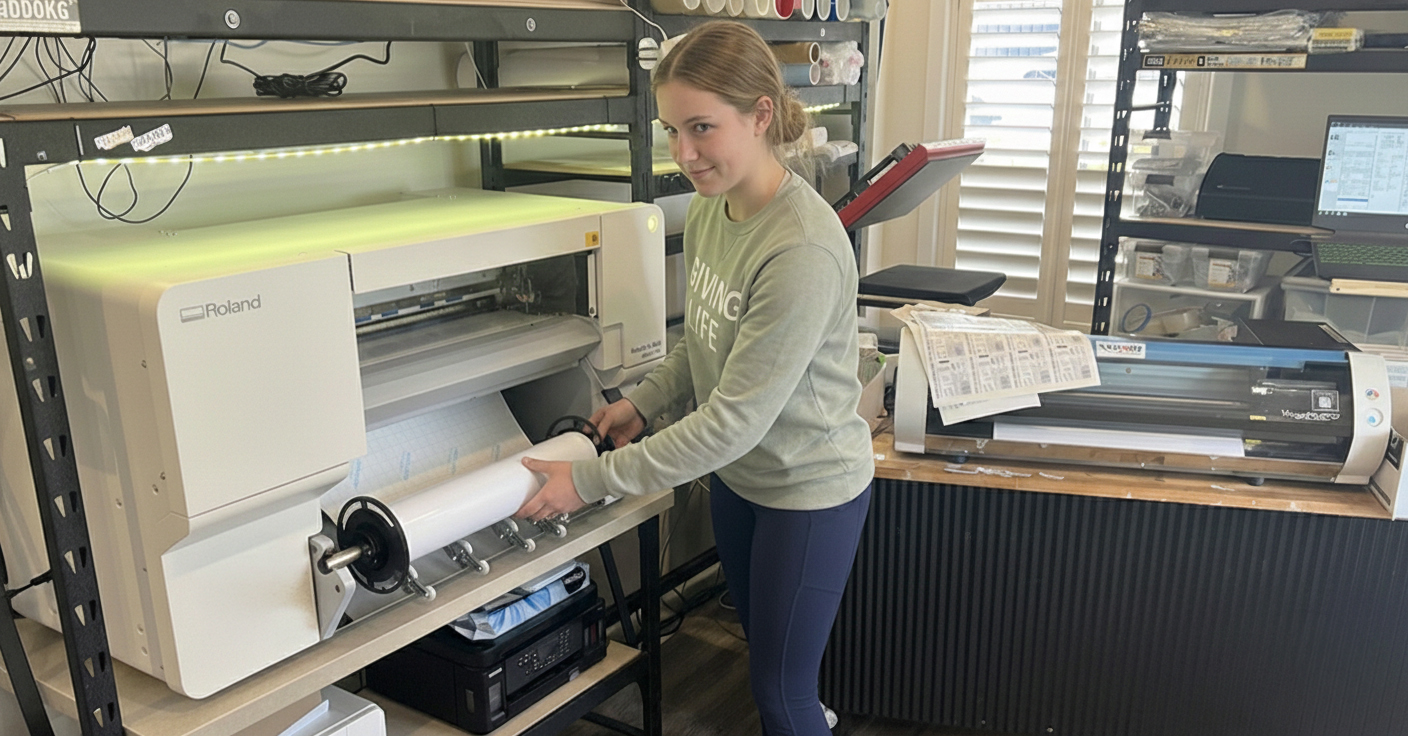

Also, it’s not silent. It’s quiet enough to run in my spare room without disturbing the house, but you definitely hear it. Marketing photos show these machines in pristine white home offices—mine lives in my spare room surrounded by boxes of vinyl and packaging materials because that’s reality!

The reality: a functional workspace that prioritizes productivity over Instagram aesthetics

Emma’s Advice for Anyone Considering This Journey

RGB UK: If someone reading this is thinking about buying a desktop print cutter, what would you tell them?

Emma: I’d give them the honest version nobody on YouTube provides:

1. Start with strategy, not equipment. Before spending a penny, identify your niche. Not “stickers”—that’s not a niche. What specific problem will you solve for which specific customers? What expertise do you have that others don’t? If you can’t answer that clearly, don’t buy equipment yet.

2. Calculate realistic break-even. How many units at what price with what margin do you need to sell monthly to cover costs? Be brutally honest about time investment. If you can work 20 hours monthly and your effective hourly rate would be £6, that’s not a business—that’s an expensive hobby.

3. Have financial cushion. You’ll be operating at a loss for months. Can you genuinely afford £400-£500 monthly expenses for six months while building the business? If that would cause financial stress, wait until you’re in a more stable position.

4. Buy quality equipment. Cheap machines seem attractive, but reliability and support matter enormously when this is your income. I don’t regret the BN2-20A investment for a second.

5. Accept it’s a real job. This isn’t passive income. You’re starting a service business that requires consistent work. If you hate customer service, hate social media, or don’t have time for admin, reconsider.

6. Don’t quit your day job prematurely. My teaching salary funded this until it became profitable. I know people who quit stable jobs to “pursue their passion” and ended up stressed and broke. Build the side business to £2,000+ monthly profit consistently before considering that leap.

7. Measure everything. Track every expense, every hour worked, every product margin. I have a detailed spreadsheet that tells me exactly which products are profitable and which are wasting my time. Data removes emotion from business decisions.

RGB UK: Any final thoughts?

Emma: Yes—be honest with yourself about why you’re doing this. If it’s because you need extra income and you’ve carefully evaluated the opportunity, great. If it’s because Instagram makes it look fun and easy, pump the brakes. This is hard work that can be financially rewarding if approached strategically, but it’s not a magic money printer.

For me, it’s been worth it. I’m making £1,000-£1,500 monthly profit, I enjoy the creative work, and I’m helping families who genuinely need my SEN resources. But I put in the work, found my niche, and had realistic expectations. That’s the formula.

Key Takeaways: Can a Desktop Print Cutter Pay for Itself?

Yes, but with important caveats:

- Timeline: Expect 7-10 months to break even on initial investment with consistent effort

- Time commitment: 30-40 hours monthly minimum for meaningful profit

- Income potential: £800-£2,000 monthly profit realistic for part-time operation in right niche

- Niche matters enormously: Specialist knowledge beats trendy products

- Profit margins: Target 60%+ to make it worthwhile; 30-40% margins barely cover time investment

- Equipment quality: Professional machines like the BN2-20A provide reliability and quality that justify premium pricing

- Market saturation is real: Avoid oversaturated niches unless you have significant competitive advantage

- It’s a proper job: Not passive income—requires consistent work and business management

Emma’s bottom line: “A desktop print cutter can absolutely pay for itself and generate meaningful income, but approach it as a serious business venture requiring expertise, capital, and consistent work—not a quick side hustle.”

Additional Resources

If Emma’s story resonates and you’re seriously considering starting a print cutting business, here are resources that might help:

- Roland BN2-20A Desktop Printer/Cutter Details

- Roland Print & Cut Equipment Range

- Media & Materials for Print Cutting

- Roland Inks & Consumables

Disclaimer: Emma Richardson participated in this interview voluntarily and received no compensation. Revenue and profit figures are based on her self-reported data. Individual results will vary significantly based on niche, location, effort, and market conditions. This article is intended for informational purposes and does not constitute business or financial advice.